Vehicle safety glass: MPA NRW tests for the global market

In the test laboratory for automotive safety glass, all safety-relevant properties of the glazing of a vehicle type are inspected.

The mechanical strength, fracture behaviour, resistance to the environment and the optical properties of the glass or plastic are tested.

The laboratory for safety glass is Technical Service of KBA.

The test laboratory for safety glass is designated by the Federal Motor Transport Authority (KBA) as Technical Service for approval tests of vehicle safety glazing. This designation as well as the accreditations of MPA NRW enable the approval of vehicles equipped with these glazings on many important markets around the world.

MPA NRW is accredited as a testing laboratory for vehicle glazing by:

- the German Accreditation Body ("Deutsche Akkreditierungsstelle", DAkkS) for tests in accordance with UN Regulation No. 43 (formerly ECE Regulation No. 43) and § 22a StVZO TA No. 29,

- the Automotive Manufacturers Equipment Compliance Agency (AMECA) for testing in accordance with US ANSI/SAE Z26.1-1996 resp. FMVSS No. 205,

- MOTC Taiwan for Vehicle Safety Testing Directions (VSTD), Item 25-1, Item 25-2 and Item 25-3.

Testing includes toughened safety glass, laminated safety glass, plastic glazing*), insulating glass and films for subsequent application to vehicle glazing. Such approval tests form the basis for general component type-approvals (national), international UNECE approvals ("E1 marking") and extensions of existing EC type-approvals ("e1 marking") as well as national type-approvals of other states.

In addition, tests according to the American ANSI standard for "DOT marking" are also carried out.

MPA NRW is also listed for safety glass tests in the Australian government's ROVER system, so that test reports from the safety glass laboratory can be used for Australian vehicle approvals.

___________________________________________

*) The laboratory for safety glass has a special competence for the testing of automotive plastic glazing.

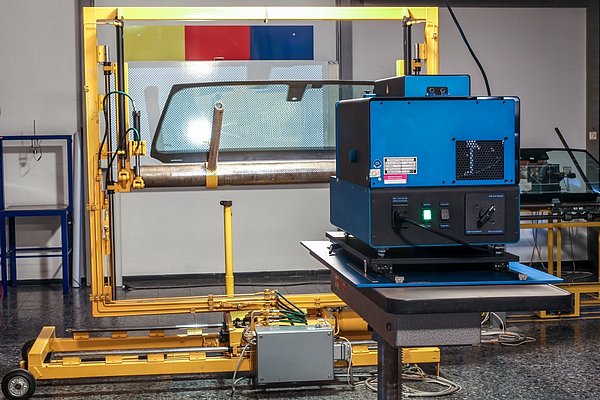

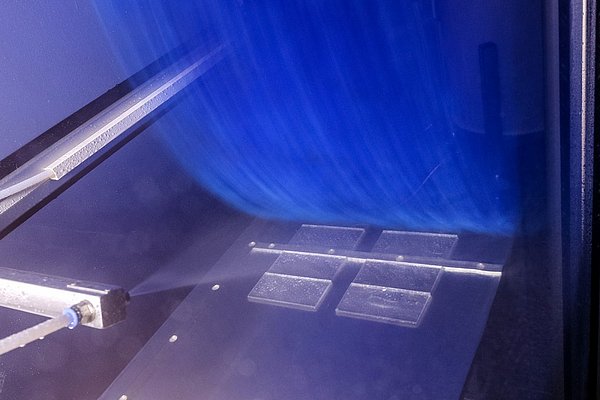

In addition to the monolithic plastic single panes, this also applies to plastic insulating glazing, plastic laminates (plastic laminated glass) and plastic windshields. In addition to more than 40 years of experience, the laboratory for safety glass has all the necessary testing equipment for testing plastic glazing. Among other things, test facilities are available for the headform test with deceleration measurement and for the so-called triple abrasion test (wiper, car wash and sand drop test), which can be carried out on the outer surface of the plastic glazing as an alternative to the Taber test.

KBA certifies “Excellent Quality”

The test laboratory for automotive safety glass was once again awarded “Excellent Quality” by the Federal Motor Transport Authority (KBA) on May 14, 2025.

As the body that issues road traffic approvals for vehicles and vehicle parts in Germany, the KBA regularly evaluates the expert reports of its Technical Services as part of a supplier assessment.